Our factory is speciality in manufacturing Auto Mould,Commodity Mould,Crate Mould,Table Mould,Chair Mould,Tub Mould,SMC Mould,Compression Mould...

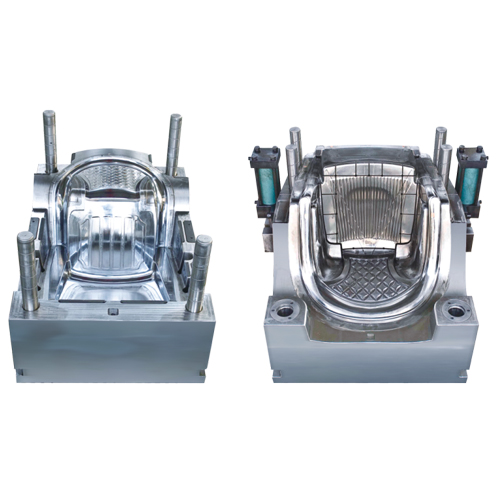

Plastic chair mould

China Diguang mold is professional in making and exporingt all kinds of plastic table molds. Including large plastic table, sand table, imitation rattan imitation table, plastic folding tables.

We can offer you:

1.Professional suggestion of the product market

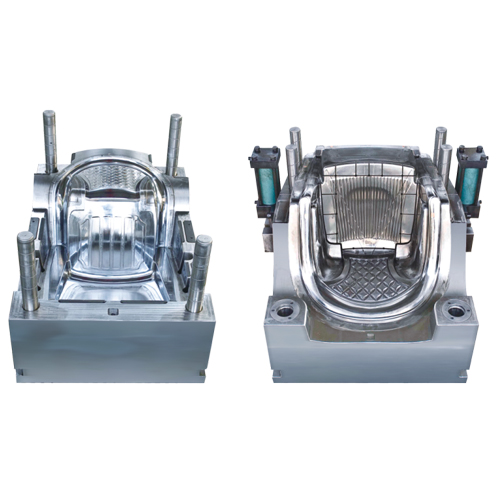

2.Prompt part design and mold design

3.Prototype and Moldflow analysis

4.Good quality mold steel and High-quality mold processing

5.Weekly mold processing schedule,mold trial video and report

6.CMM part dimension report

7.Mold inspection report before shipment

8.Always thoughtful service

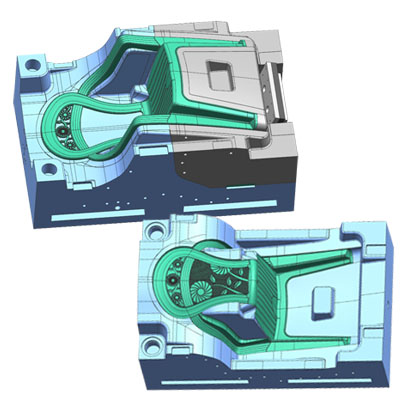

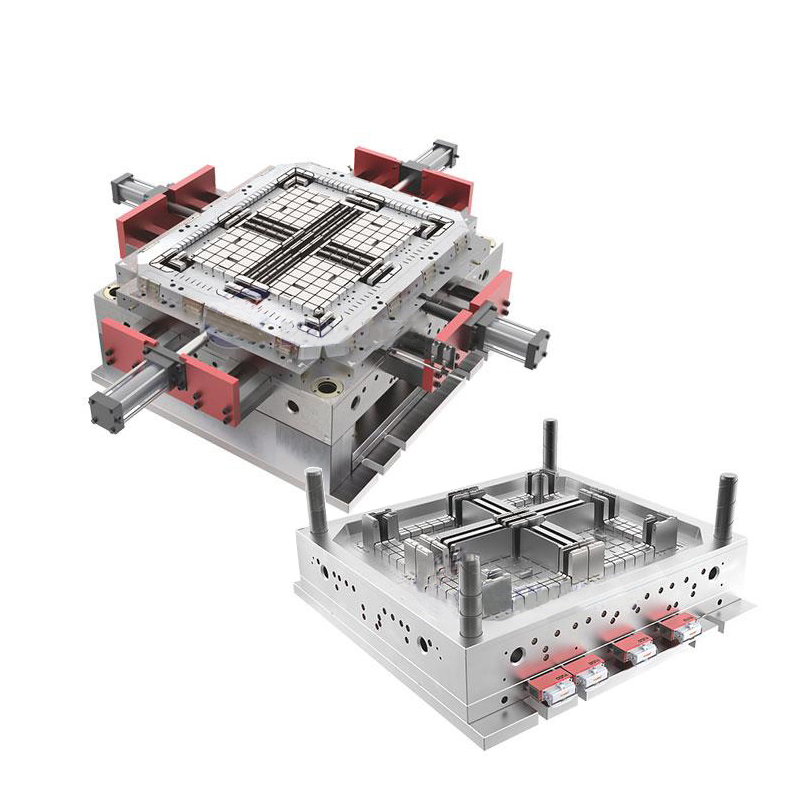

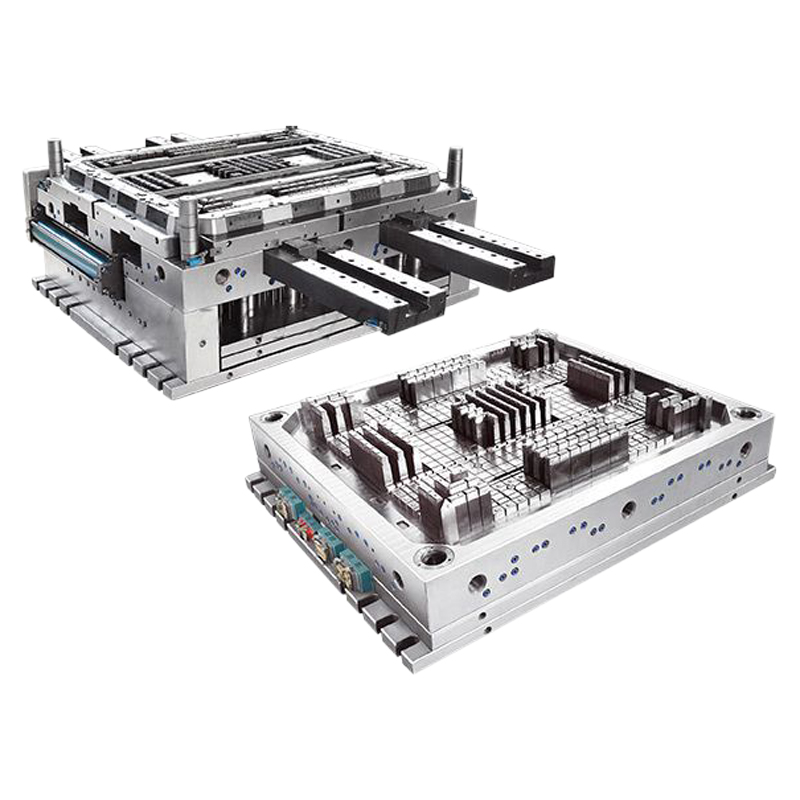

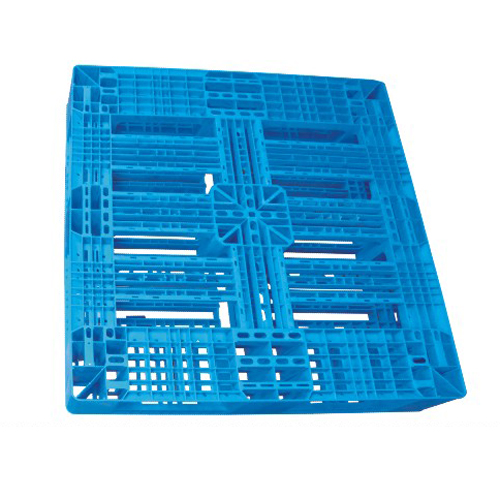

Pallet Mould

Pallet Mould is one of our main mould series, Wherever high mechanical strength and rigidity are paramount, SUNRISE Pallet mould prepreg on rolls is the ideal solution. Workable by hot press moulding, the multifunctional structural parts are well suited above all for large surfaces.

DG has a modern laboratory with presses with capacities from 200t up to 2,000t to form high-precision parts in a wide range of shapes and sizes for trial and test purposes. Synchronisation control accounts for constant wall thickness even with highly complex or extremely thin-walled parts.

To be one of leader Pallet mould Makers in China, DG Pallet Mould contains Pallet Pallet Moulds, Tray Pallet Moulds, Plastic Auto Pallet Moulds, Door Pallet moulds, Bathroom Pallet moulds, Manhole Cover Pallet Moulds and other Pallet moulds.

DG Pallet mould is becoming more and more famous Pallet mould maker in plastic injection moulding industry, would like to be your honest Pallet mould suppliers.

commodity molds

Commodity Moulds,Daily Necessities Mould,Daily Use Molds,Commodity Mould Maker

Raw material:PP,PC,ABS

Mould base:45#,S50C,HASCO LYM,LKM,DME,etc

Core/cavity steel:P20,718,Thyssen1.2738,

Cavity:Single/multi

Colour:demand on customer requirement

Dimension: demand on customer requirement

Runner:Hot/cold

Delivery method:by sea

Packing:wooden case

Leadtime:60ays

Lifetime:Guarantee 1,000,000 shots

1.Commodity Mould design-----checked by R&D

2.Commodity Mould base&cavity steel purchase----the supplier must own the steel certificate

3.Commodity Mould Electrodes----inspection by Mould Monitor

4.Core&cavity dimension----inspection by Mould Monitor

5.Mould Assembly----insepction by Mould Monitor

6.Commodity Mould First Trial ,sent the OK samples and reports to customer for approval

7.Final inspection for pre-shipment

8.Package inspection by the QC

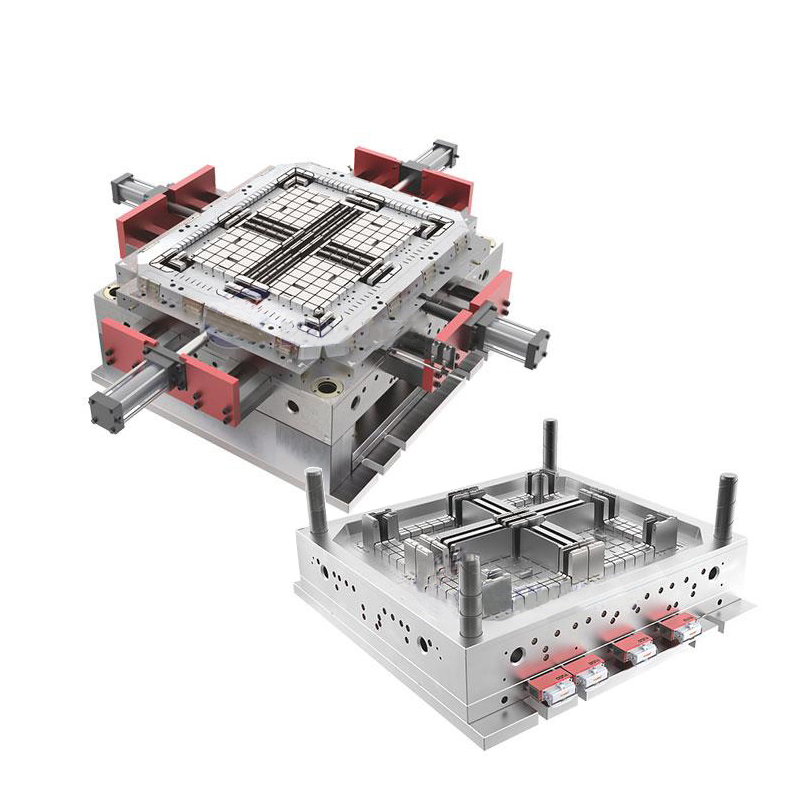

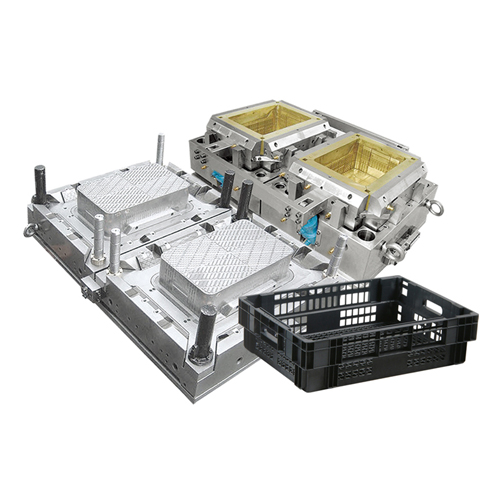

Turnover box mould

Plastic crate mould handle area venting solution:this is an important issue, as because when the crate was loaded and the people carried the crate, the two handle area will be the biggest force focused. If on the mould, this area’s air venting is not perfect, there will be a very obviously jointing line, that is a place where the damage always come from.

DG MOULD is the leading Chinese crate mould manufacturer in the world, we have developed more than 1000 sets various crate moulds such like, bottle crate mould, fish crate mould, fruit crate mould, bread crate mould.

Our question are:

do you need a high production performance crate mould?

do you have the automatic ejection function problem in the 4 side collapsible core cola bottle crate mould?

do you want to use the recycled plastic material to molding the single-usecrate?

If you need all these questions to be solved and clarified, please come to SUNRISE Mould for crate mould and plastic crate molding solutions!

Paint Barrel Mould

1. Design with specified cost and time criteria.

The old rule of “good, fast and cheap” still applies. There always seems to be time for rework or adjustment after meeting that ultra short deadline, but it is better to allow reasonable time in the design stage for review and correction.

2. Make sure your design specifications can be produced using existing technology.

Programs like Solidworks and the availability of rapid prototyping can provide early insight into potential problems that might occur before metal gets cut. Provide the engineering group with full specifications, do not leave anything out. If something is left out here it will cost time and money to fix later in the process.

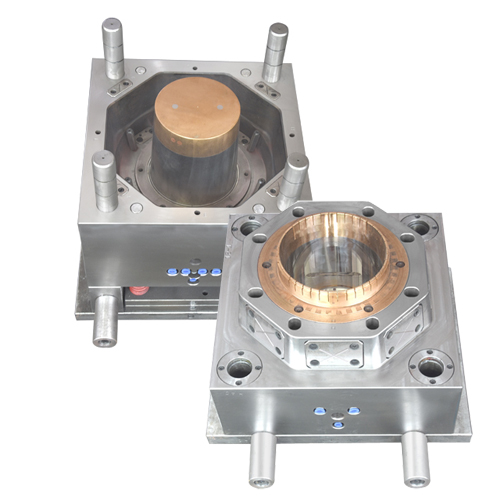

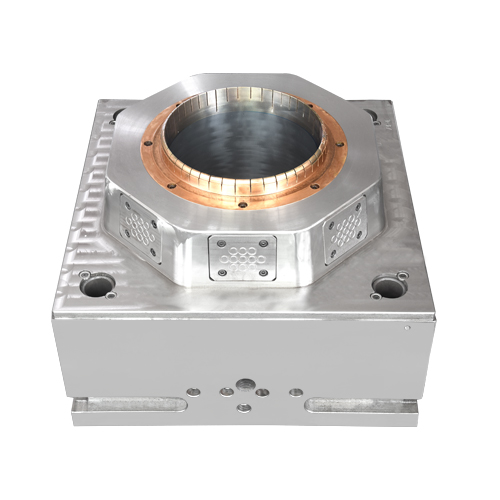

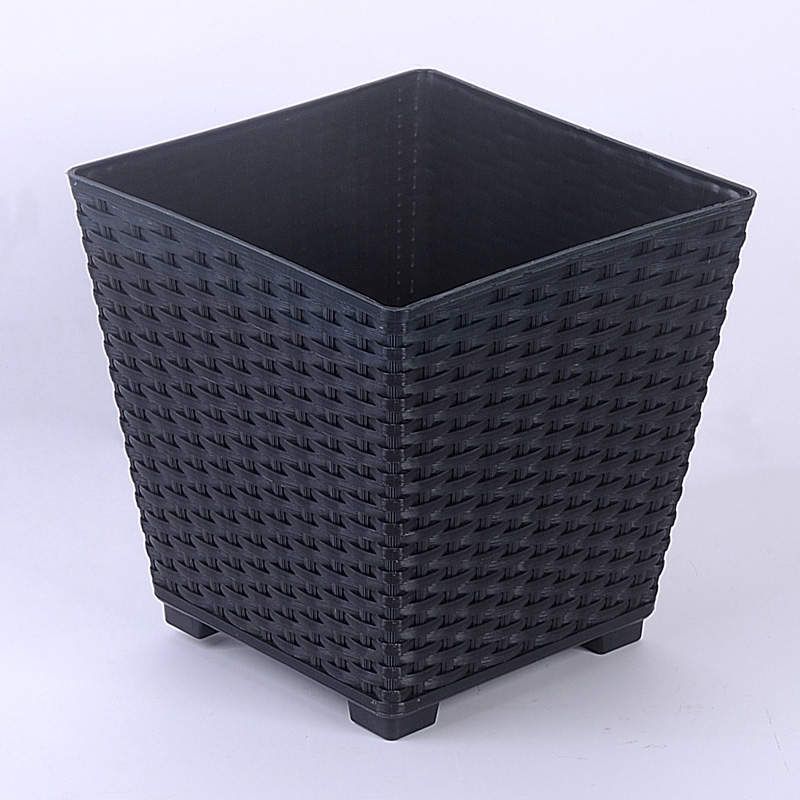

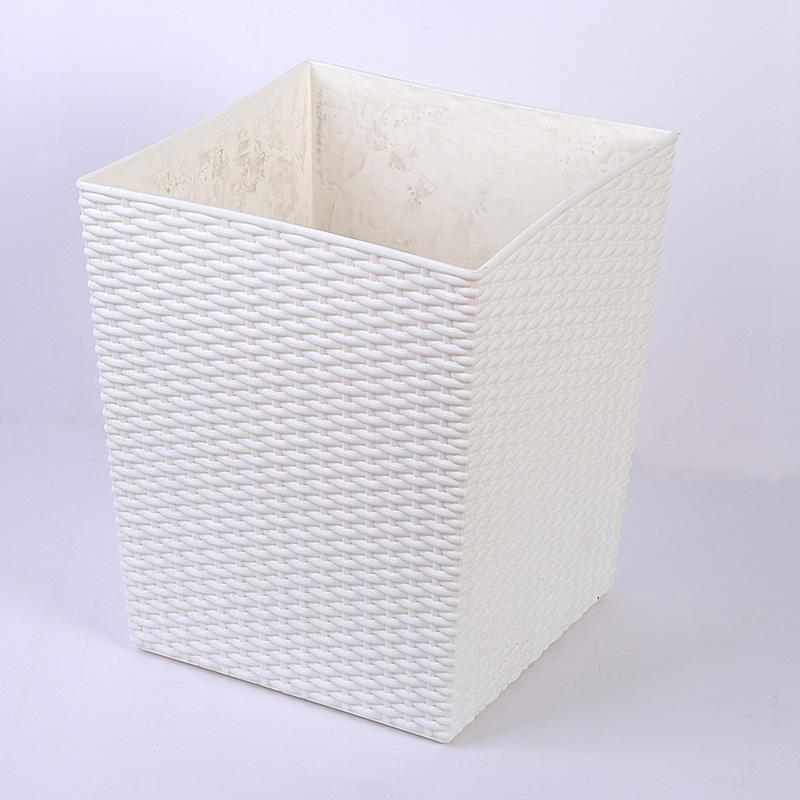

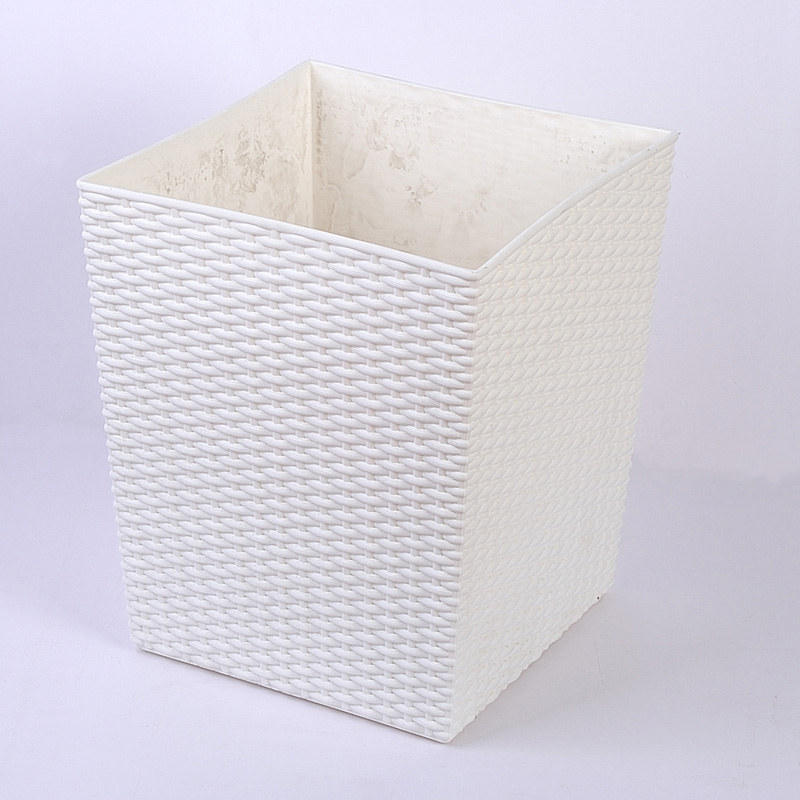

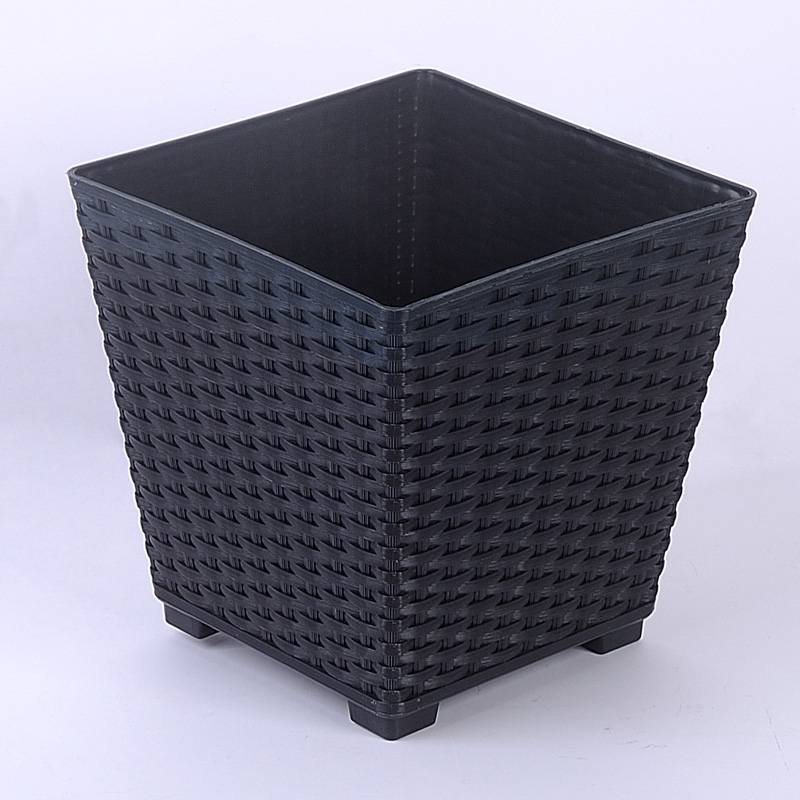

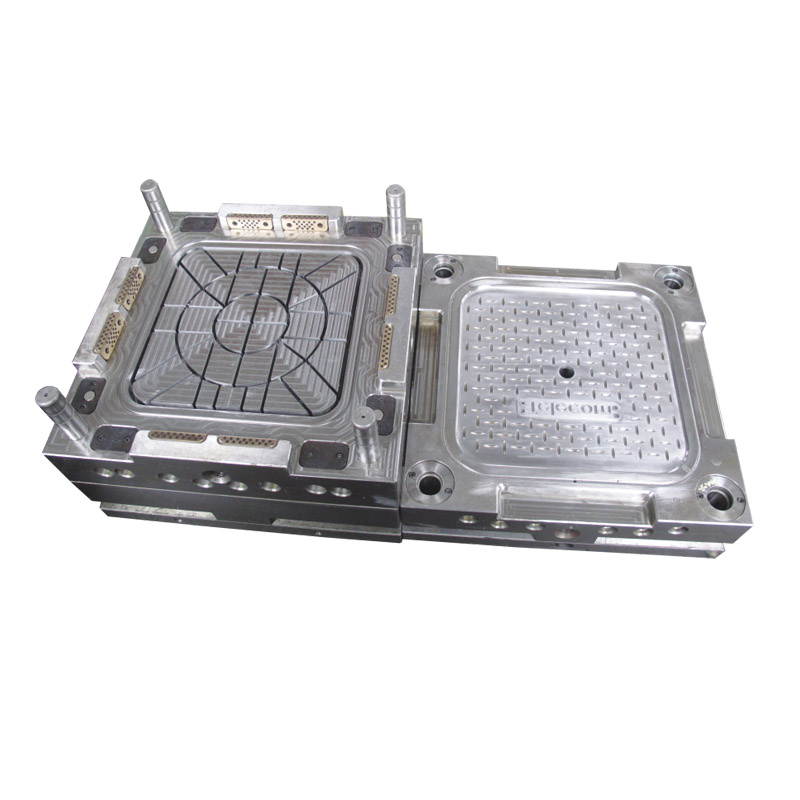

Flower Pot mould

Plastic Flower Pot Tray Mould

1. High quality & Favorable price

2. Rich experiences & Fast Delivery

3. ODM & OEM are welcomed

Mould Details:

Cavity: Single/Multiple

Mould base: HSCO, LKM etc.

Mould material: PP, PC, PS, PE, PU, PVC, ABS, PMMA etc.

Design software: UG, PROE, CAD, Solidworks etc.

Quality Standard: SGS

Delivery time: 15~60 days

Specification: Depends on customer's requirements.

DG Mould is professional in designing and manufactoring precision plastic tooling.

Our business scope:

1. Plastic mold design & fabrication

2. Injection molding

3. Plastic Mold products processing

If your are interested in any of our products, please feel free to contact us.

We sincerely want to establish long-term business relationship with you!

Commodity Mould Case Show

Pallet Mould

Pallet Mouldcommodity molds

commodity moldsTurnover box mould

Turnover box mouldPaint Barrel Mould

Paint Barrel MouldFlower Pot mould

Flower Pot mouldFinishing Box Mould

Finishing Box MouldFinishing Box Mould

Finishing Box Mouldcommodity molds

commodity moldscommodity molds

commodity moldscommodity molds

commodity moldscommodity molds

commodity moldscommodity molds

commodity moldsBlow mold 04

Blow mold 04Blow mold 03

Blow mold 03Blow mold 02

Blow mold 02Blow mold

Blow moldFlower Pot mould 09

Flower Pot mould 09Flower Pot mould 08

Flower Pot mould 08Flower Pot mould 07

Flower Pot mould 07Flower Pot mould 06

Flower Pot mould 06Flower Pot mould 05

Flower Pot mould 05Flower Pot mould 04

Flower Pot mould 04Flower Pot mould 03

Flower Pot mould 03Flower Pot mould 02

Flower Pot mould 02Flower Pot mould 01

Flower Pot mould 01Pallet Mould 04

Pallet Mould 04Pallet Mould 03

Pallet Mould 03Pallet Mould 02

Pallet Mould 02Pallet Mould

Pallet Mould