Our factory is speciality in manufacturing Auto Mould,Commodity Mould,Crate Mould,Table Mould,Chair Mould,Tub Mould,SMC Mould,Compression Mould...

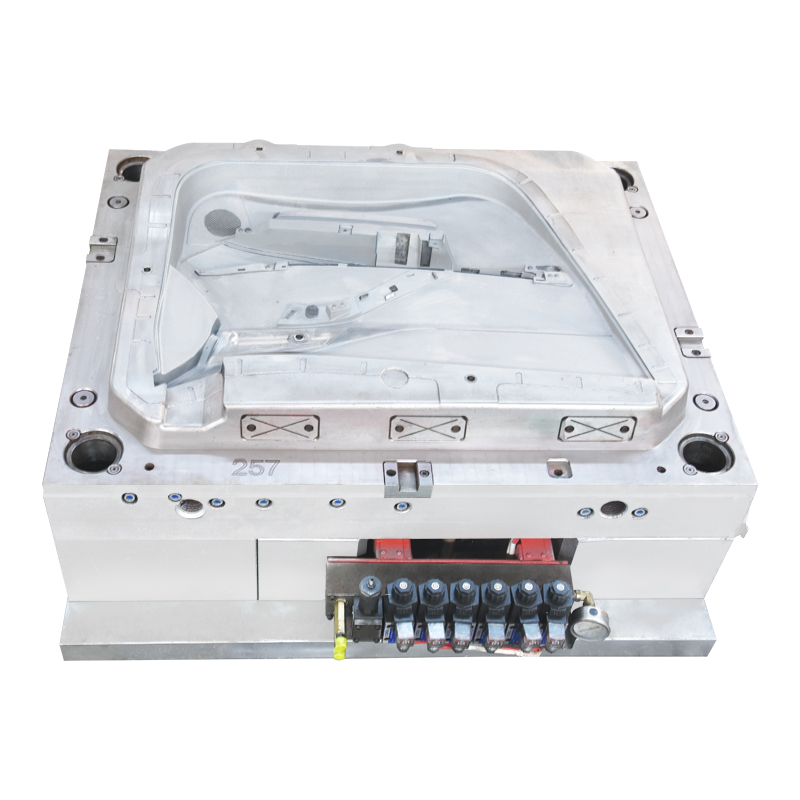

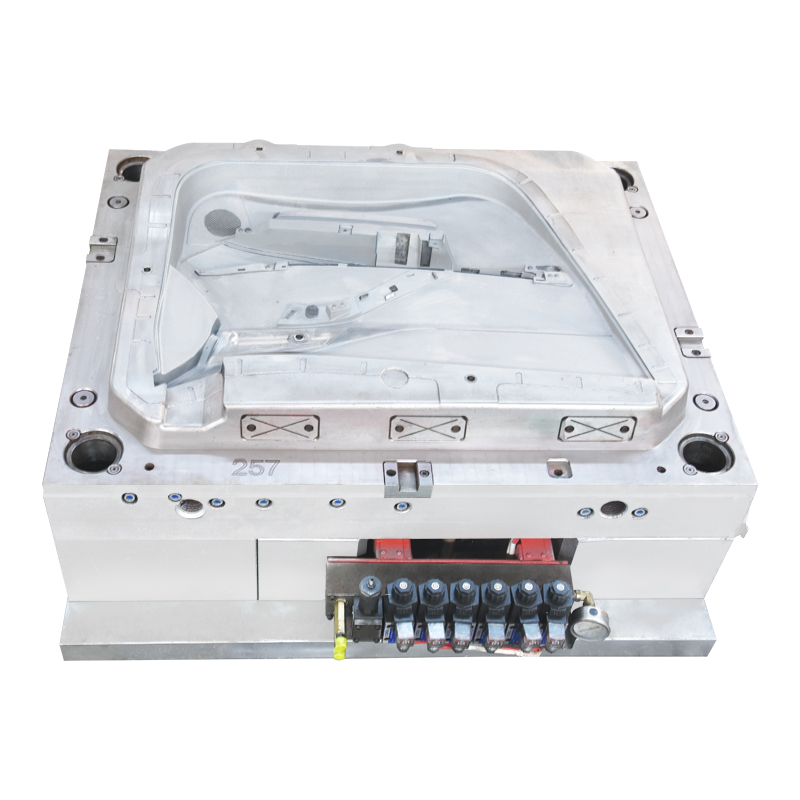

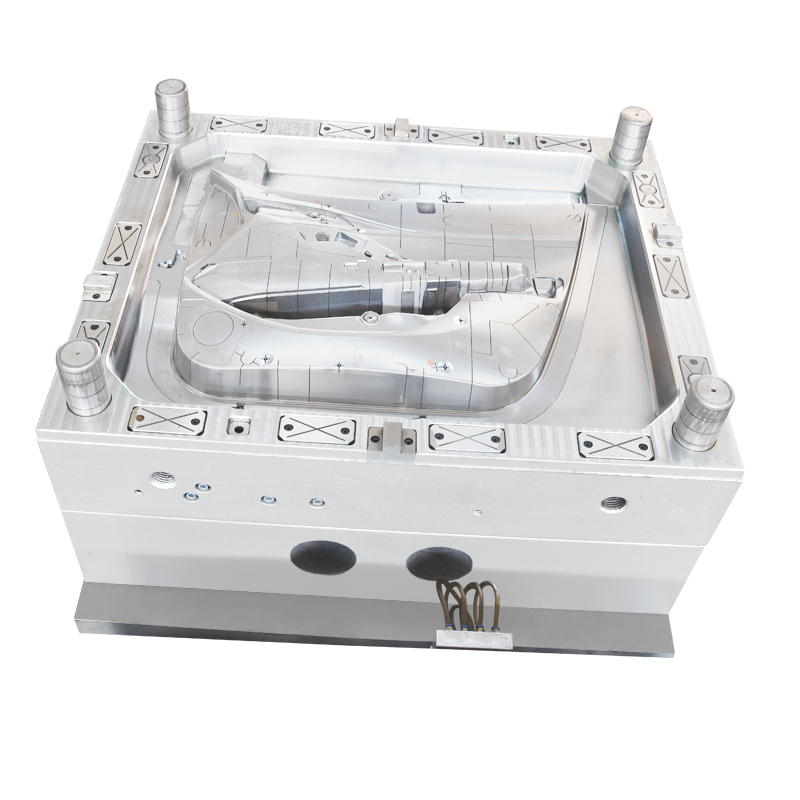

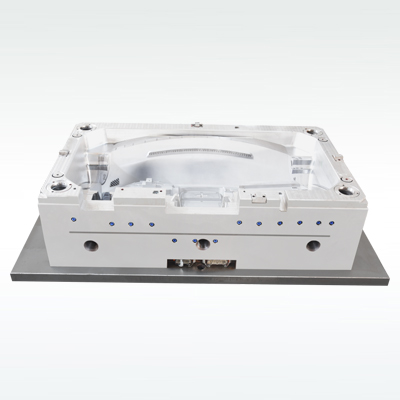

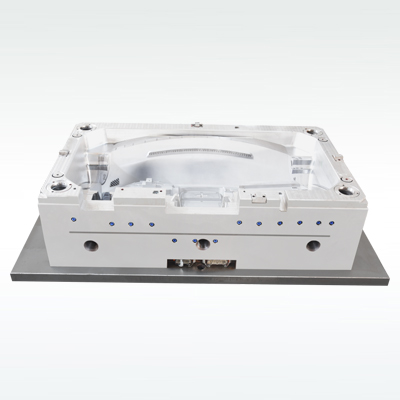

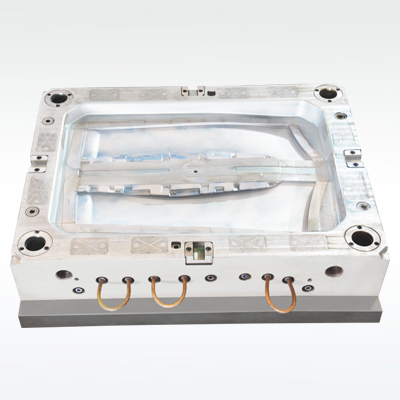

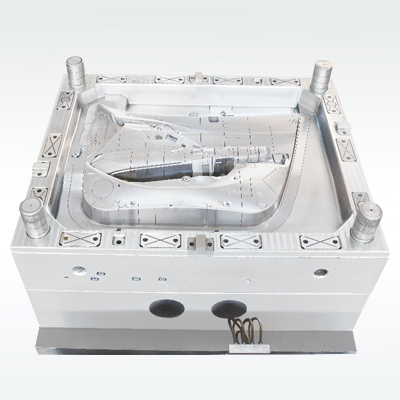

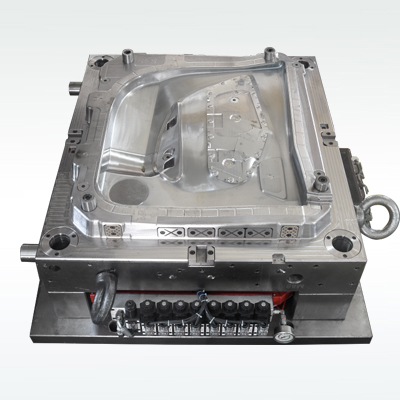

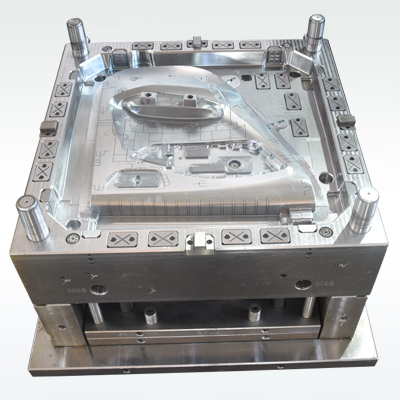

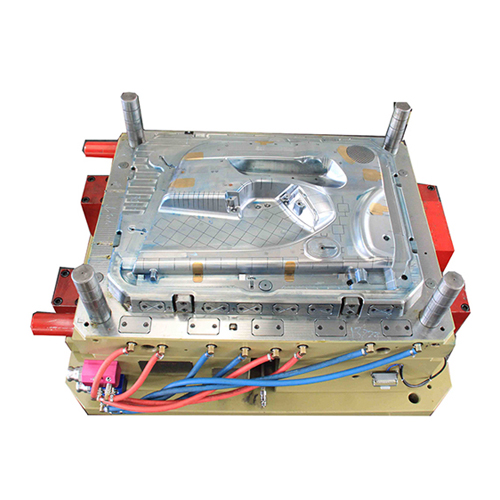

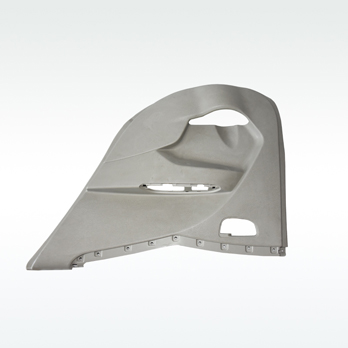

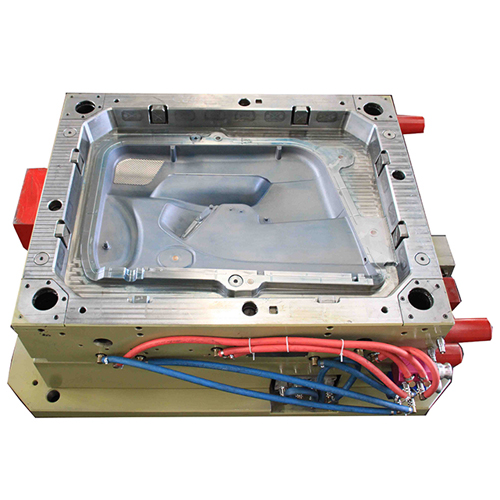

AUTO DOOR PANEL MOULD

DG Mould has focusing on the production of automotive mold, For example front auto door and rear auto door; auto door with speaker mesh and auto door w/o speaker mesh.

Any sharp, shrink mark, melting line, scratch and under filled can’t appear on the part of auto door.

DG has consider the following issues during auto door mould designing and manufacturing:

1.Reasonable size of mould base.

2.Water line must be applied as much as possible, and the dia. of water line should be large as much as possible.

3.Injection gate needed more than 3 drops for the auto door mold. The melt line will appear at the two point meeting area.

4.Ensure the ejecting system be safe and reasonable. Since many lifter and ejector for auto door mould, there for has to avoid the sharp caused by the small error during auto door mould manufacturing.

5.Design the reasonable departing line, it will be convenient for auto door mould assembly and manufacturing.

6.Avoid air exhaust when the auto door mould with speaker mesh.

AUTO DOOR PANEL MOULD Case Show

Auto door panel mould

Auto door panel mouldAuto door panel mould

Auto door panel mouldAuto door panel mould

Auto door panel mouldAuto door panel mould

Auto door panel mouldAuto door panel mould

Auto door panel mouldAuto door panel mould

Auto door panel mouldAUTO DOOR PANEL MOULD 02

AUTO DOOR PANEL MOULD 02AUTO DOOR PANEL MOULD 03

AUTO DOOR PANEL MOULD 03AUTO DOOR PANEL MOULD 04

AUTO DOOR PANEL MOULD 04AUTO DOOR PANEL MOULD 05

AUTO DOOR PANEL MOULD 05Auto Door Panel Sample 08

Auto Door Panel Sample 08Auto Door Panel Sample 09

Auto Door Panel Sample 09Auto Door Panel Sample 10

Auto Door Panel Sample 10Auto Door Panel Sample 11

Auto Door Panel Sample 11Auto Door Panel Sample 12

Auto Door Panel Sample 12Auto Door Panel Sample 13

Auto Door Panel Sample 13Auto Door Panel Sample 14

Auto Door Panel Sample 14Auto Door Panel Sample

Auto Door Panel SampleAuto Door Panel Sample

Auto Door Panel SampleAuto Door Panel Sample

Auto Door Panel SampleAuto Door Panel Sample

Auto Door Panel SampleAuto Door Panel Sample

Auto Door Panel Sample