Our factory is speciality in manufacturing Auto Mould,Commodity Mould,Crate Mould,Table Mould,Chair Mould,Tub Mould,SMC Mould,Compression Mould...

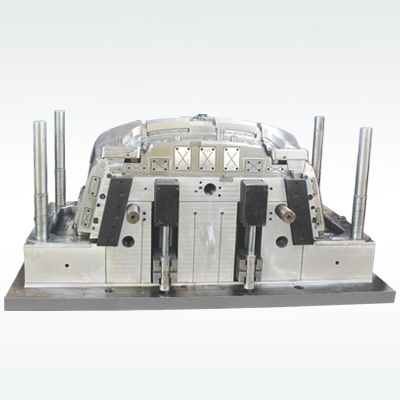

Auto Bumper Mould

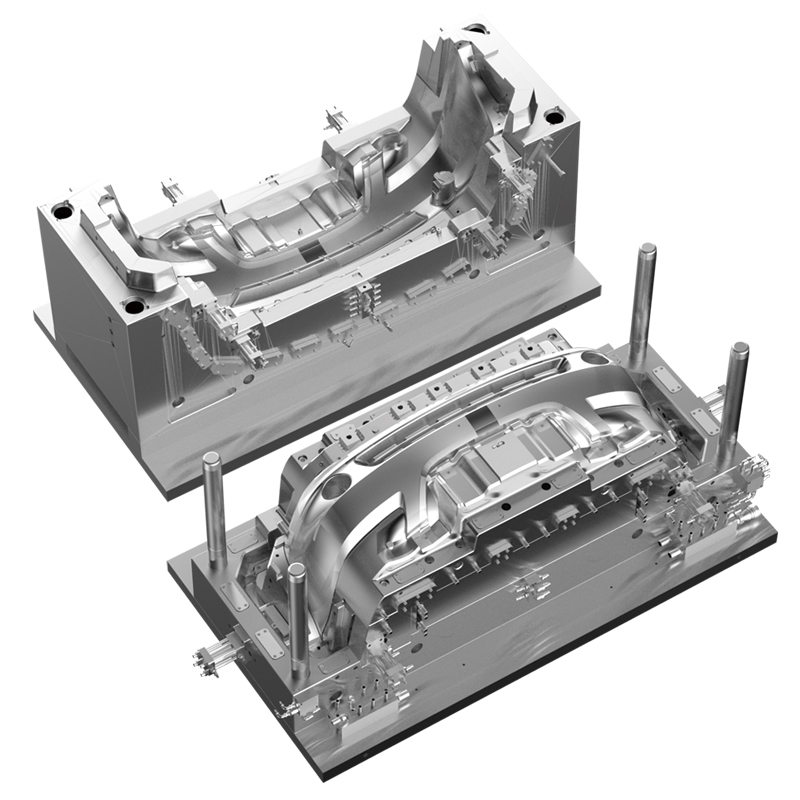

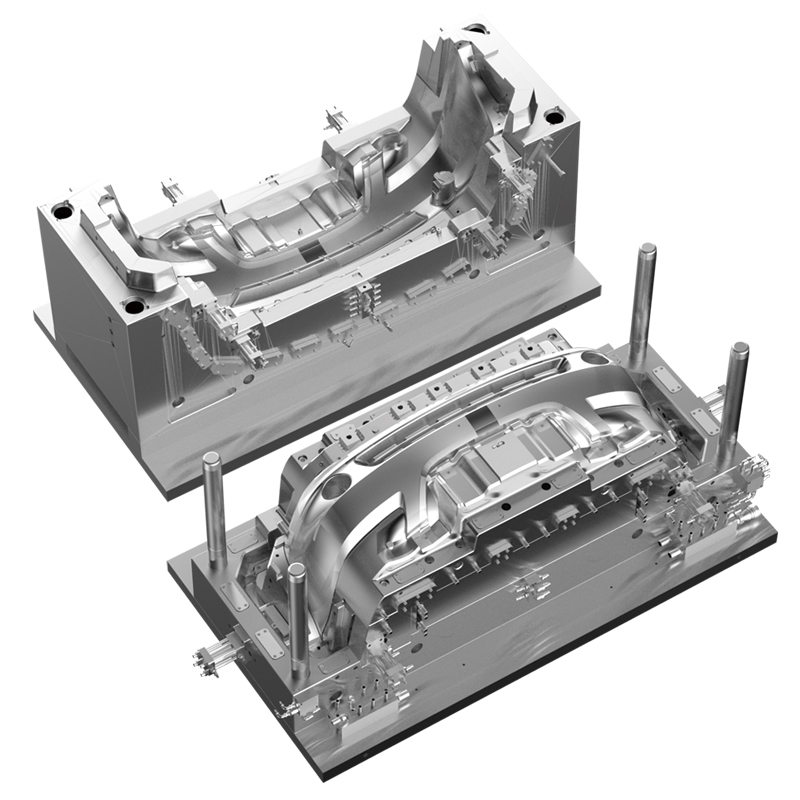

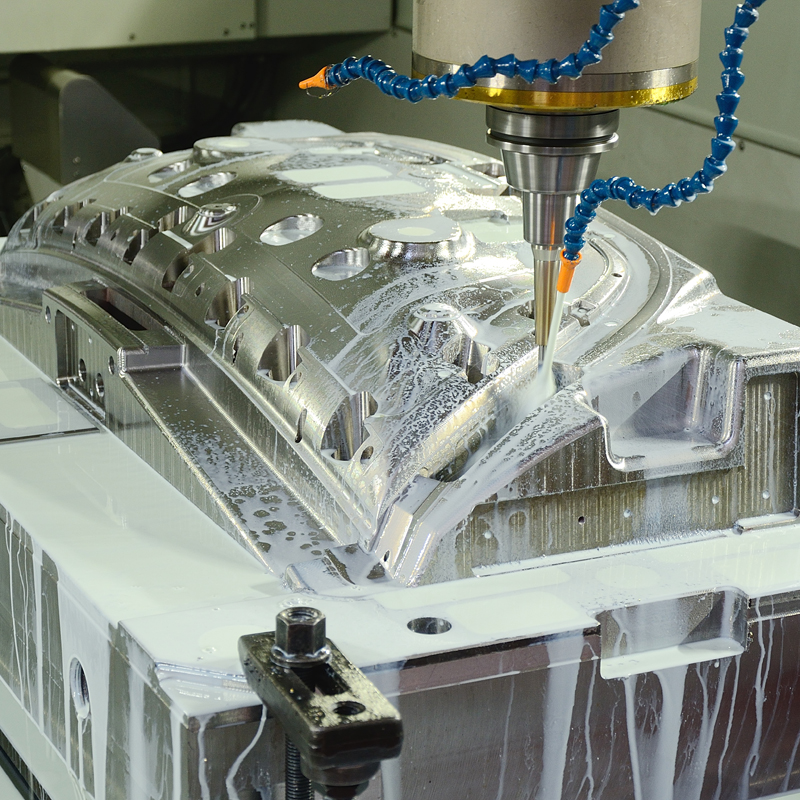

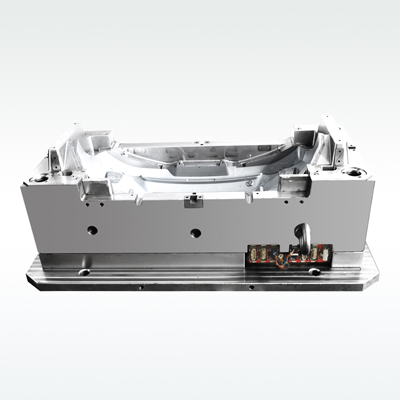

Diguang has been supplying the front auto bumper mould, back auto bumper mould and auto grill mould to different auto makers. With the improving of customer’s request for surface of car bumper mold, the structure of outer departing surface can’t meet the need of market. So Diguang have been accumulating the experience and importing the advanced technology in auto mould.

1.Structure of inner departing surface: Diguang can master the structure and set the departing line on the non exterior surface to be ejected, so it will avoid small step on the surface of auto bumper and avoid the issue of cutting flash. At finally, it helps to realize the smooth surface of auto bumper.

2.The location of injection gate: The reasonable allocation of injection gate could reduce the pressure difference of cavity, it directly affects the quality of auto bumper.

3.The location of taking injection part: Leave the injection part on cavity side or core side? We have to consider the reasonable structure of auto bumper mould ejection system.

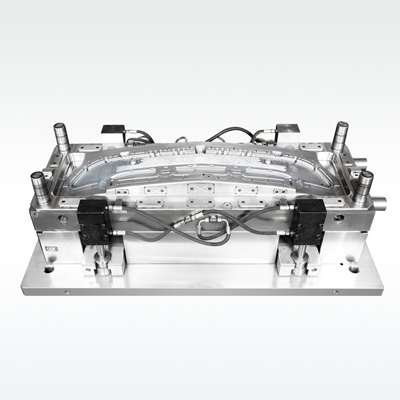

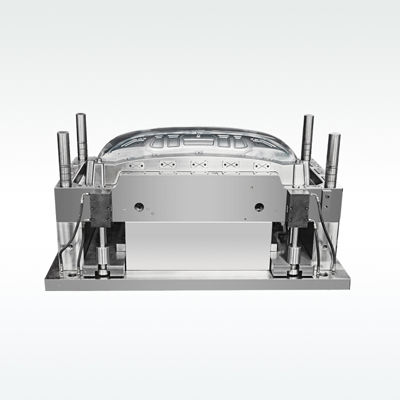

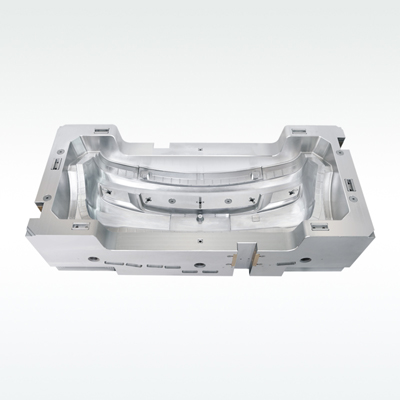

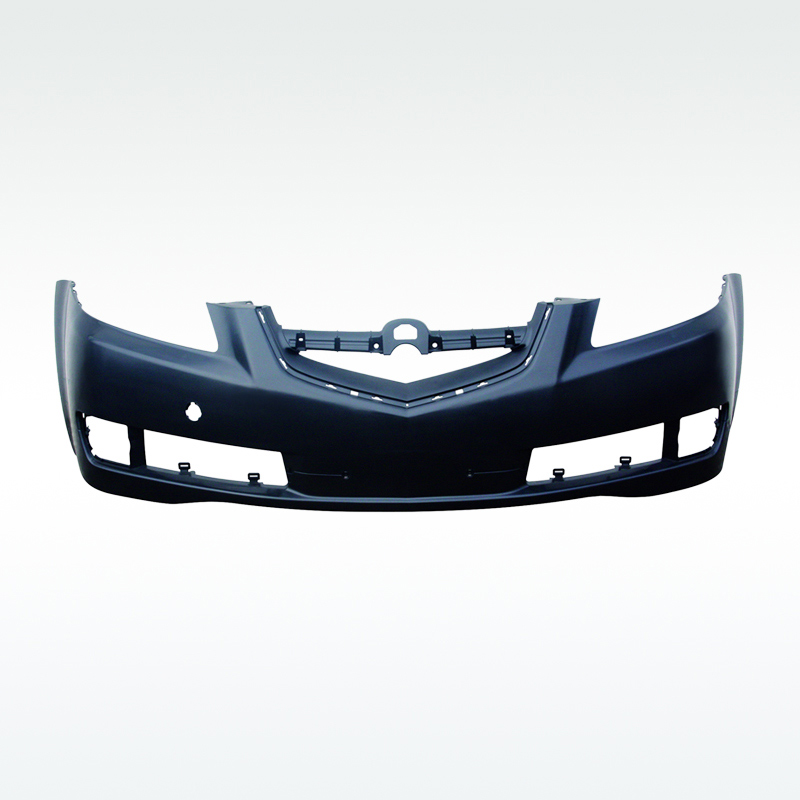

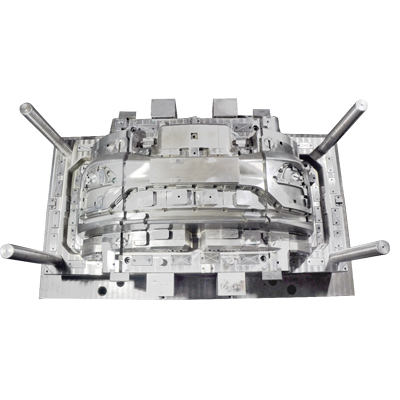

Bumper mould Case Show

Auto Bumper Mould 01

Auto Bumper Mould 01Auto Bumper Mould 02

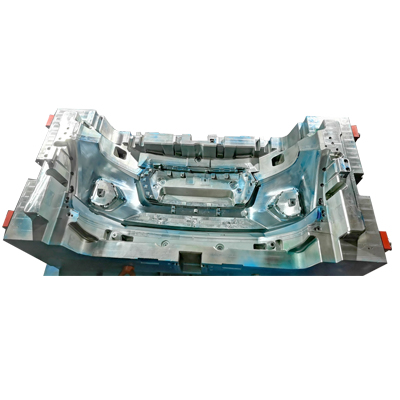

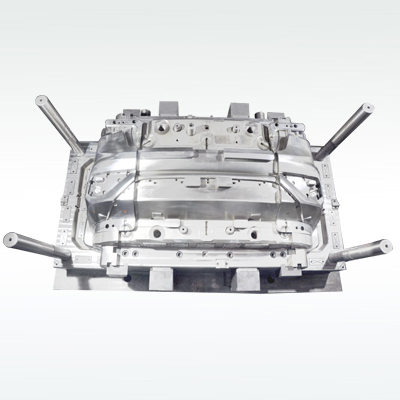

Auto Bumper Mould 02Auto Bumper Mould 03

Auto Bumper Mould 03AUTO BUMPER MOULD 04

AUTO BUMPER MOULD 04AUTO BUMPER MOULD 05

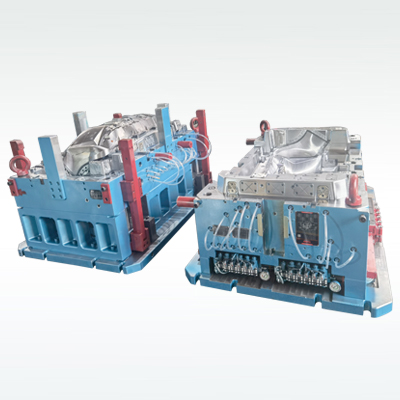

AUTO BUMPER MOULD 05AUTO BUMPER MOULD 06

AUTO BUMPER MOULD 06AUTO BUMPER MOULD 07

AUTO BUMPER MOULD 07Bumper Mould sample 09

Bumper Mould sample 09Bumper Mould sample 10

Bumper Mould sample 10Bumper Mould sample 11

Bumper Mould sample 11Bumper Mould sample 12

Bumper Mould sample 12Bumper Mould sample 13

Bumper Mould sample 13Bumper Mould sample 14

Bumper Mould sample 14Bumper Mould sample 15

Bumper Mould sample 15Bumper Mould sample 16

Bumper Mould sample 16Bumper Mould

Bumper MouldBumper Mould

Bumper MouldBumper Mould

Bumper MouldBumper Mould

Bumper MouldBumper Mould

Bumper MouldBumper Mould

Bumper MouldBumper Mould

Bumper MouldBumper Mould

Bumper Mould